Bottle caps may seem like small, simple components, but they play a vital role in packaging by ensuring the safety, freshness, and convenience of bottled products. Whether for beverages, pharmaceuticals, cosmetics, or household goods, selecting the right bottle cap is an essential step in the packaging process. The purchase of bottle caps requires careful consideration of various factors including material, design, compatibility, and regulatory compliance to meet product needs and consumer expectations.

The diversity of bottle cap designs corresponds to the variety of products and packaging requirements in the market. This diversity means selecting the right cap involves more than simply matching sizes.

Material Selection

One of the considerations in purchasing bottle caps is the material. The common materials include:

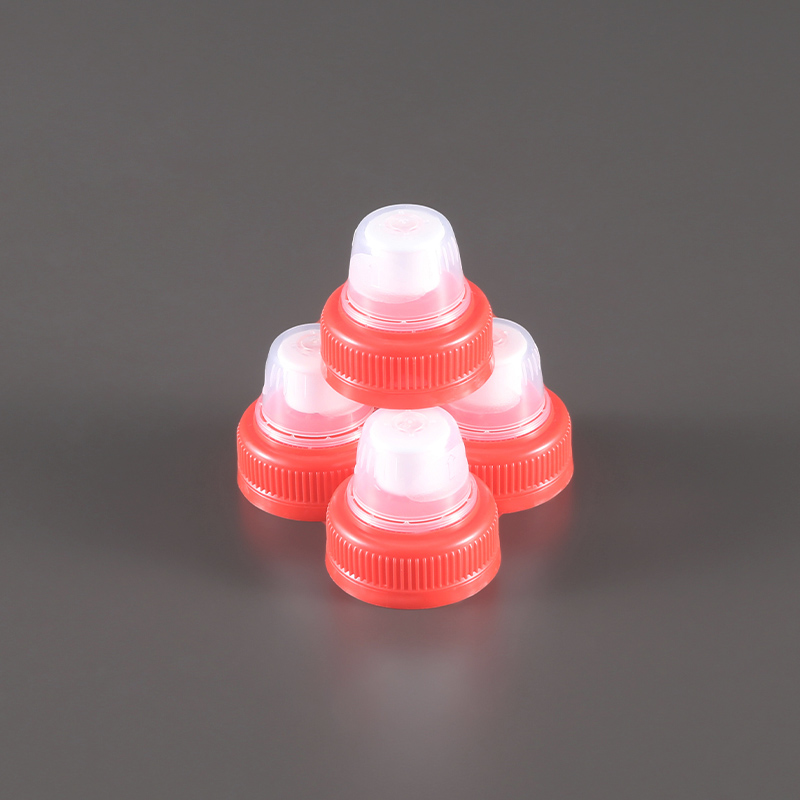

Plastic (Polypropylene, Polyethylene): Widely used due to cost-effectiveness, versatility, and ease of molding. Plastic caps can be designed with various features such as flip-tops, dispensing spouts, or tamper-evident seals. They also offer good chemical resistance but may vary in recyclability depending on local facilities.

Metal (Aluminum, Steel): Often used in beverage and pharmaceutical industries for their durability and premium feel. Metal caps are commonly found in crown caps (beer bottles) and screw caps. They offer barrier properties but can be prone to corrosion unless coated.

Composite Materials: Some bottle caps combine materials for enhanced performance, such as plastic linings inside metal caps to improve sealing and chemical resistance.

The choice of material depends largely on the product's nature, shelf life requirements, and environmental considerations.

Compatibility with Bottle Neck and Thread

Proper fit between the bottle cap and bottle neck is fundamental. Caps must match the bottle's neck finish, thread design, and diameter precisely to ensure an effective seal and ease of use.

Neck Finish: Bottle necks come in standard sizes defined by diameter and thread style (e.g., 28mm, 38mm). Caps must be purchased to correspond to these dimensions.

Thread Profile: Some bottles use continuous threads, others use snap-on or lug-style caps. The cap's internal threading must align with the bottle for secure closure.

A mismatch can bring about leakage, difficulty in opening, or compromised product integrity.

Closure Design and Functionality

Beyond basic sealing, bottle caps offer a range of functional features that should be considered based on end-user needs:

Tamper-Evident Caps: These include bands or seals that break upon opening, assuring consumers that the product has not been previously opened.

Child-Resistant Caps: Designed for safety, especially for pharmaceuticals and household chemicals, requiring specific actions to open.

Dispensing Caps: Such as flip-tops, sport caps, or dropper tips, these provide controlled flow for ease of use.

Sealing Liners: Internal liners or gaskets made of materials like foam, PE, or induction seals improve barrier properties and prevent leakage.

The choice depends on product type, regulatory requirements, and consumer preferences.

Quality and Regulatory Compliance

Bottle caps must meet certain quality standards to ensure safety and performance. When purchasing bottle caps, it is critical to verify that suppliers adhere to relevant regulations:

Food Contact Safety: For edible or beverage products, caps must comply with FDA or equivalent food safety standards, ensuring materials do not leach harmful substances.

Pharmaceutical Standards: Caps used for medicines often require certification for sterility, biocompatibility, and child safety.

Environmental Regulations: Increasingly, buyers are seeking caps made from recyclable or biodegradable materials, aligning with sustainability goals.

Reliable suppliers provide documentation such as certificates of compliance, batch testing results, and traceability to maintain quality assurance.

English

English Español

Español 中文简体

中文简体